CHEAP SOLAR PANELS CHANGE THE RULES OF DESIGN OF FACILITIES IN COMMERCIAL ROOFING

Optimizing a design of a photovoltaic installation for commercial roofs has changed significantly in recent years. When, 6 or 7 years ago, the price of the solar photovoltaic module was about 5 times higher than today, the design usually passed through maximizing production, ie place modules looking perfectly south and the optimum angle (about 30 °) for most of the Spanish territory. Moreover, obtaining a sufficiently high premium at the same time pushed toward optimization.

Today, with the existence of cheap solar panels, about 5 times cheaper than a few years ago, without the existence of any premium, the objective has changed. Now, our maximum for design is to obtain the best possible return on the installation, which in this case does not have to be the solution that maximizes production.

TILT AND BEST ORIENTATION OF SOLAR MODULES

Current trends in the design of solar roofs are increasingly using system optimization as a way to reduce the costs of installation and maintenance.

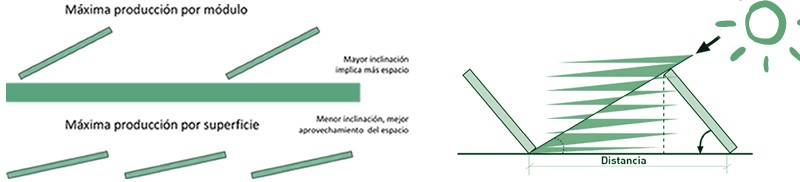

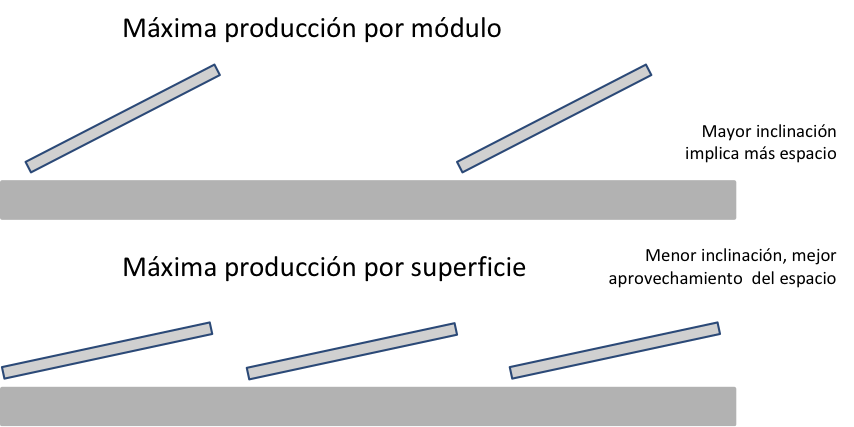

Each system designer faces a dilemma. To maximize sunlight in each module, the designer can tilt the module in its best efficiency point, needing some space between rows of solar panels. But this will reduce the number of modules that can fit on a given surface. Alternatively, the designer can place the modules closer, and reduce the inclination to minimize shading. In language engineering, this is a compromise between energy density (maximum yield per module) and power density (kW maximum per square meter)

With a given surface, a lower inclination of the photovoltaic module will involve better use of the surface, ie, we can introduce more power from solar panels in the same space. The industry moves toward designs with low inclination and maximum utilization of space, maximizing energy extracted per module to obtain the maximum power per square meter of roof is sacrificed. Even in some locations, you plan to have modules oriented east and west alternatively, to maximize power installed by surface.

Current tools allow multiple simulations of the variants to find the optimum for each project. In many cases the optimum is not a seemingly obvious configuration, allowing us to maximize each project.

Given the fall in the price of modules and inverters, system optimization presents an opportunity to improve the profitability of a project. Optimization may improve performance without increasing the cost.

As a result, many engineering firms have begun to focus on the development of optimization techniques that can be applied to find the most cost-effective designs for each project, site by site. This is particularly common in commercial systems: the system size is large enough for optimization worthwhile. Each location and customer profile is original enough to require a custom scan. The optimization involves the simulation of various technical and financial options, finding the optimum overall project.

Optimization of orientation

Many roofs are not perfectly facing south. This situation forces the designer to decide between modules to match the south to maximize energy efficiency or place them in the direction of the building to maximize the number of modules that can fit on the roof.

It should also be a second criterion; what time of day energy is more valuable to the user. Some users may have a face at certain times or a higher energy consumption in others, which determines the need to account for this situation to maximize performance.

If we know that a part of the energy is to be poured, the price of electricity is higher in the afternoon, so this may be a criterion for optimization.

The correct scales of all variables derived system optimization. As mentioned, this optimization is both technically and economically.

INVERTER / DESIGN MODULE LEVEL AND TOLERANCE IN THE SHADOW

The existence of new types of inverters; three-phase string inverters, microinverters and optimizers, design options beyond the standard central inverters are opened.

Consideration of these new types of inverters creates the need to take into account different DC and AC wiring, which will be different for each option. It should also take into account the higher labor during installation, and of course the greater modularity and ease of easy replacement.

Furthermore, the optimization module level, systems can be designed allowing certain shadows. Historically a good facility design eliminated all modules that were in shadow. However, with the availability of cheap solar panels, it now makes more sense to selectively add some of these modules, especially if they are only in the shade in the winter months, when productivity is lower. Also recently only new software allows detailed calculations of the shadows, allowing rigorously analyze and evaluate losses shadows on a cost-benefit problem adding modules.

A NEW ERA OF PHOTOVOLTAIC SOLAR SYSTEMS DESIGN

When developers of photovoltaic solar systems increase their sophistication and embrace these optimization techniques can implement solar projects low cost without sacrificing quality. The time of the design of the solar field facing south and tilted 30º has come to an end. Now with lower hardware costs and more experienced developers, technicians are performing a thorough analysis of each project, realizing a lower pitch and a tight spacing can significantly improve the economics of the system, thus achieving a technical and economically optimized system.

Pol Parareda Farriol es ingeniero industrial y MBA, con más de 15 años de experiencia internacional en el sector de la energía solar fotovoltaica y las energías renovables. Actualmente Director en Tienda Solar, trabaja en el desarrollo y gestión de soluciones de autoconsumo, sistemas fotovoltaicos y almacenamiento con baterías para el mercado residencial y profesional.

A lo largo de su carrera ha ocupado puestos de responsabilidad en empresas líderes del sector como Weidmüller, SunPower, Sunco Capital y Hilti, desempeñando funciones en ingeniería, desarrollo de producto, operaciones, O&M, gestión comercial y dirección estratégica de proyectos solares, tanto a pequeña escala como en grandes plantas fotovoltaicas internacionales.

Ha liderado proyectos y equipos en Europa, Latinoamérica y Asia, participando en el desarrollo de más de cientos de MW en proyectos solares, negociación de PPAs, estrategias EPC y optimización de sistemas fotovoltaicos. Además, ha sido docente de energía solar fotovoltaica en programas de máster en energías renovables en instituciones como la Universidad Carlos III de Madrid